India Low Voltage Switchgear Market to Reach US$ 5.98 Billion by 2033

India Low Voltage Drives Market Overview

India’s industrial transformation is accelerating, and at the heart of this change lies a growing demand for smarter, energy-efficient motor control technologies. According to Renub Research, the India Low Voltage Drives (LVD) Market is projected to grow from US$ 646.52 million in 2024 to US$ 967.22 million by 2033, registering a CAGR of 4.58% during 2025–2033.

This steady expansion reflects India’s intensified focus on energy conservation, automation, and sustainable industrial practices. From manufacturing hubs to smart city infrastructure, low voltage drives are becoming critical tools in optimizing motor performance and reducing operational energy consumption.

India Low Voltage Drives Market Overview

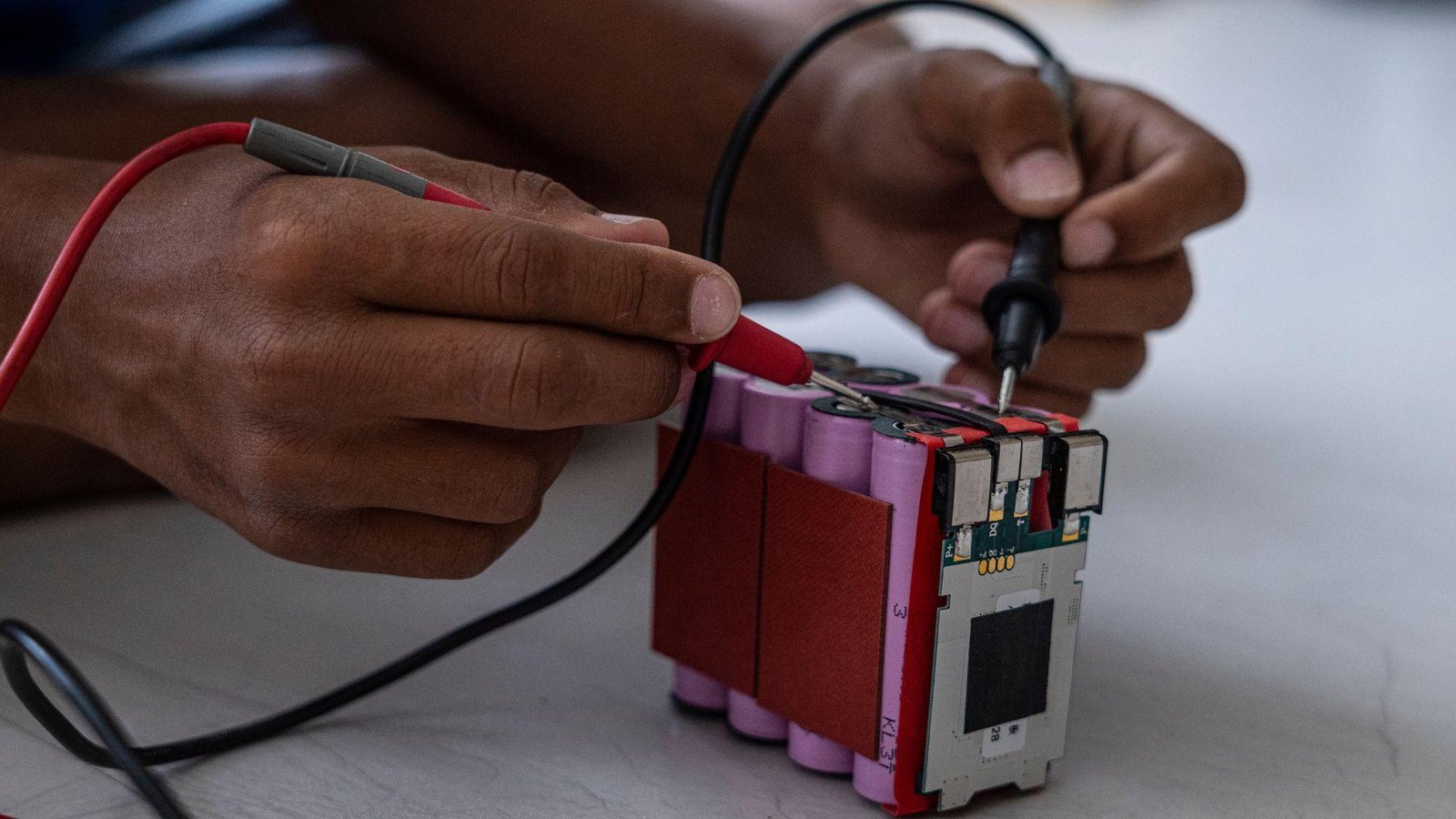

Low Voltage Drives (LVDs) are advanced motor control devices designed to regulate speed, torque, and direction in electric motors operating below 1,000 volts. These systems are widely used in sectors such as manufacturing, HVAC (heating, ventilation, and air conditioning), water treatment, oil & gas, chemicals, and renewable energy.

In India, the growing emphasis on operational efficiency and carbon reduction has significantly boosted LVD adoption. Industries are increasingly turning toward automation to improve productivity while complying with environmental regulations. By optimizing motor speed based on real-time demand, LVDs minimize energy waste, reduce mechanical stress, and extend equipment lifespan.

Government-backed initiatives such as the Perform, Achieve, and Trade (PAT) scheme under the National Mission on Enhanced Energy Efficiency (NMEEE) have further strengthened the case for energy-efficient motor systems. These programs provide a regulatory and financial framework that encourages industries to transition toward sustainable technologies.

As India continues to modernize its industrial ecosystem, LVDs are emerging as a foundational component of next-generation energy management systems.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=india-low-voltage-drives-market-p.php

Key Growth Drivers Shaping the Market

Energy Efficiency Regulations Accelerating Adoption

One of the strongest catalysts for growth in India’s LVD market is the implementation of stringent energy efficiency regulations. The PAT scheme sets mandatory energy-saving targets for energy-intensive industries. Companies that exceed their targets can trade energy-saving certificates, incentivizing investment in advanced technologies like low voltage drives.

Such policy frameworks create measurable economic benefits for industries adopting energy-efficient solutions. Reduced electricity consumption translates into lower operational expenses, improved competitiveness, and alignment with national climate commitments.

India’s broader sustainability goals, including reducing carbon intensity and expanding renewable energy integration, further amplify the importance of motor optimization technologies.

Rising Government Incentives and Industrial Modernization

Government initiatives supporting renewable energy and energy-efficient manufacturing are contributing significantly to market growth. Subsidies, tax benefits, and incentives under schemes related to clean energy and industrial modernization encourage industries to invest in advanced automation systems.

Programs promoting electric mobility, industrial digitization, and “Make in India” manufacturing reforms indirectly strengthen the demand for LVDs. These drives are essential in ensuring optimized power usage across production lines, assembly units, and energy-intensive processes.

By reducing energy consumption and improving system reliability, LVDs offer both economic and environmental advantages—making them attractive across diverse sectors including automotive, chemicals, and power generation.

Growing Environmental Awareness Among Industries

Environmental sustainability has become a boardroom priority. Indian corporations are increasingly aligning with global ESG (Environmental, Social, and Governance) standards. Energy efficiency is often the first and most impactful step toward reducing carbon footprints.

Low voltage drives play a crucial role in this transition. By matching motor speed to actual process demand, they eliminate unnecessary power consumption. This results in lower greenhouse gas emissions and improved resource efficiency.

Industries are also recognizing the long-term operational benefits of LVD integration, including lower maintenance costs and enhanced system reliability. As sustainability shifts from compliance to competitive advantage, adoption rates are expected to rise steadily.

Market Challenges Hindering Wider Penetration

High Initial Investment Costs

Despite long-term savings, the upfront cost of purchasing and installing LVD systems remains a barrier, particularly for small and medium-sized enterprises (SMEs). Installation expenses, system integration requirements, and workforce training add to capital expenditure.

While large enterprises can absorb these costs and benefit from scale efficiencies, SMEs often delay adoption due to budget constraints. Bridging this affordability gap through financing models and policy support will be essential to unlock broader market penetration.

Dependence on Imported Components

India’s LVD industry relies heavily on imported electronic components and semiconductor technologies, particularly from countries like China. This dependence exposes the market to supply chain disruptions, currency fluctuations, and tariff uncertainties.

Geopolitical tensions and global trade constraints can affect pricing stability and delivery timelines. For SMEs, such volatility creates operational challenges.

Encouraging domestic manufacturing under industrial policy reforms could mitigate these risks and support long-term market resilience.

Regional Insights: Diverse Growth Across India

North India: Industrial Expansion and Smart Infrastructure

North India commands a significant share of the national LVD market. The region hosts diverse industries including textiles, HVAC manufacturing, water treatment plants, and heavy engineering units.

Government initiatives such as Smart Cities development and industrial corridor expansion have stimulated demand for energy-efficient motor systems. As urban infrastructure modernizes, LVD applications in HVAC and water management systems are increasing.

However, challenges such as high installation costs and limited skilled technicians persist. Addressing these issues through vocational training and policy incentives will be crucial to sustaining growth.

South India: Manufacturing and Electronics Hub

South India remains a powerhouse for industrial automation. States such as Tamil Nadu, Karnataka, Telangana, Andhra Pradesh, and Kerala are at the forefront of adopting advanced drive technologies.

Chennai has emerged as a major electronics manufacturing hub, particularly within the Electronics Manufacturing Services (EMS) corridor linking Sriperumbudur and Oragadam. Global companies such as Dell Technologies, Nokia Corporation, and Foxconn operate facilities in this region, driving demand for automation and energy optimization systems.

Coimbatore, often referred to as the “Manchester of South India,” also contributes significantly to industrial demand. The region’s robust network of engineering institutes ensures a steady supply of skilled professionals capable of integrating advanced drive systems.

East India: Emerging Industrial Potential

East India—including West Bengal, Odisha, Bihar, Jharkhand, and the northeastern states—is gradually integrating LVD technologies into its industrial framework.

Infrastructure initiatives such as the East Coast Economic Corridor (ECEC) are boosting industrialization. Major ports like Kolkata and Paradip are driving manufacturing expansion in steel, cement, textiles, and food processing sectors.

However, awareness gaps and limited skilled manpower in tier-2 and tier-3 cities slow adoption. Increased training programs and vendor outreach initiatives are likely to accelerate market development in this region.

West India: Industrial and Chemical Powerhouse

Although not detailed extensively above, West India—including Maharashtra and Gujarat—remains one of the strongest industrial bases in the country. The concentration of chemical plants, automotive manufacturers, and power generation units creates sustained demand for efficient motor control systems.

As renewable energy projects expand across western states, LVD applications in power generation and grid optimization are also expected to rise.

Market Segmentation Insights

By Product Type

· AC Drives

· DC Drives

· Servo Drives

· Variable Frequency Drives (VFDs)

Variable Frequency Drives are witnessing significant adoption due to their versatility and compatibility with industrial automation systems.

By Power Range

· Micro Drives

· Low-End Drives

· Medium-End Drives

· High-End Drives

Medium- and high-end drives are increasingly used in large-scale industrial facilities requiring higher load capacities.

By Application

· HVAC

· Pumps

· Conveyors

· Compressors

HVAC and pump applications account for a substantial share due to their widespread use in commercial and industrial facilities.

By End Users

· Manufacturing

· Oil & Gas

· Automotive

· Chemicals

· Power Generation

Manufacturing remains the dominant segment, supported by automation trends and productivity enhancement initiatives.

Competitive Landscape: Key Industry Players

The India LVD market is moderately competitive, with domestic and international companies strengthening their presence through innovation and localized manufacturing.

Major players include:

· ABB India Ltd

· Siemens Limited

· Danfoss A/S

· Hitachi Hi-Rel Power Electronics Private Limited

· Yaskawa India Private Limited

· Rockwell Automation Inc.

· Schneider Electric SE

· Kirloskar Electric Company Ltd.

· Amtech Electronics India Limited

These companies compete through product innovation, localized service networks, digital integration, and strategic partnerships. Financial strength and technological expertise remain key differentiators in the evolving market landscape.

Future Outlook: Sustainable Growth Through Automation

Between 2025 and 2033, India’s Low Voltage Drives market is poised for consistent expansion. The push toward industrial digitization, renewable energy integration, and carbon reduction will continue to shape demand.

Advancements in smart drives integrated with IoT platforms and predictive maintenance capabilities are expected to enhance operational efficiency further. As manufacturing ecosystems adopt Industry 4.0 practices, LVDs will become indispensable components of connected production environments.

While challenges such as high capital investment and import dependency remain, domestic manufacturing initiatives and policy reforms may help mitigate these risks.

Final Thoughts

India’s Low Voltage Drives market reflects the country’s broader industrial and environmental transformation. With Renub Research forecasting the market to reach US$ 967.22 million by 2033 at a CAGR of 4.58%, growth prospects remain solid and sustainable.

Energy efficiency is no longer optional—it is a strategic imperative. As industries strive to balance productivity, cost control, and sustainability, low voltage drives will continue to play a pivotal role in optimizing operations and reducing environmental impact.

The next decade will likely see India strengthen its position as a hub for smart, energy-efficient industrial solutions—powered significantly by the expanding adoption of low voltage drive technologies.