Silicone Market Global Forecast: Emerging Trends & Investment Opportunities 2033

Silicone Market Size and Forecast 2026–2036

The global silicone market is set for consistent and stable expansion, supported by rising demand across construction, automotive, electronics, healthcare, energy, and personal care industries. The market is projected to grow from US$ 16.83 Billion in 2025 to US$ 26.88 Billion by 2034, registering a Compound Annual Growth Rate (CAGR) of 5.34% from 2026 to 2034.

Silicone’s versatility, durability, flexibility, and resistance to extreme temperatures make it one of the most valuable high-performance materials in modern industrial and consumer applications. As industries prioritize performance, sustainability, and reliability, silicone continues to strengthen its role as a critical material in next-generation technologies and infrastructure development.

Global Silicone Industry Overview

Silicone is a synthetic polymer composed primarily of silicon, oxygen, carbon, and hydrogen. Unlike conventional plastics, silicone can withstand extreme temperatures, moisture, UV exposure, and chemical stress without losing performance integrity. Its unique molecular structure enables exceptional flexibility, strength, and environmental resistance.

Silicone materials are available in several forms depending on application requirements:

· Elastomers

· Fluids

· Resins

· Gels

· Specialty compounds

These materials are widely used in construction sealants, automotive components, electronic insulation systems, medical devices, personal care products, renewable energy systems, and household goods.

In recent years, silicone has gained widespread global acceptance due to its durability, safety profile, and environmentally adaptable properties. In medical applications, silicone is valued for its biocompatibility and sterilization compatibility. In electronics and renewable energy, its insulation capabilities and thermal stability make it indispensable.

As industrial sectors evolve toward more advanced and sustainable technologies, silicone continues to serve as a backbone material.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=silicone-market-p.php

Key Growth Drivers in the Global Silicone Market

Expanding Demand from Construction and Infrastructure

The construction sector remains one of the largest consumers of silicone-based products. Rapid urbanization, infrastructure expansion, and renovation activities worldwide are increasing demand for silicone sealants, adhesives, and coatings.

Silicones provide:

· Long-term durability

· UV resistance

· Weatherproofing

· Enhanced insulation

· Improved energy efficiency

Green building initiatives and sustainable architecture trends further support silicone adoption. Silicone materials help improve airtightness, reduce energy consumption, and enhance structural longevity.

In March 2023, Dow expanded its silicone sealant product line with the DOWSIL PV Product Line, specifically designed for photovoltaic module assembly. This innovation highlights silicone’s growing role in renewable energy and sustainable construction.

As governments and developers prioritize energy-efficient buildings, silicone demand within infrastructure projects is expected to rise steadily.

Rising Use in Automotive and Transportation

The automotive and transportation industries are major growth engines for silicone materials. Silicone is widely used in:

· Gaskets and seals

· Hoses and tubing

· Electronic insulation

· Thermal management systems

· Lubrication components

Its ability to withstand high temperatures and harsh environments makes it ideal for engine compartments and electronic systems.

The rise of electric vehicles (EVs) has further strengthened demand. Silicone plays a vital role in battery protection, thermal regulation, and electronic insulation within EV systems. As automotive manufacturers focus on lightweight and high-performance materials to improve fuel efficiency and safety, silicone continues to gain traction.

In December 2022, Dow introduced its SILASTIC™ SA 994X Liquid Silicone Rubber (LSR) series, designed for smarter and more sustainable mobility applications. The innovation demonstrates how silicone technology supports next-generation vehicle manufacturing.

Growing Adoption in Healthcare and Electronics

Healthcare and electronics represent two of the fastest-growing silicone application segments.

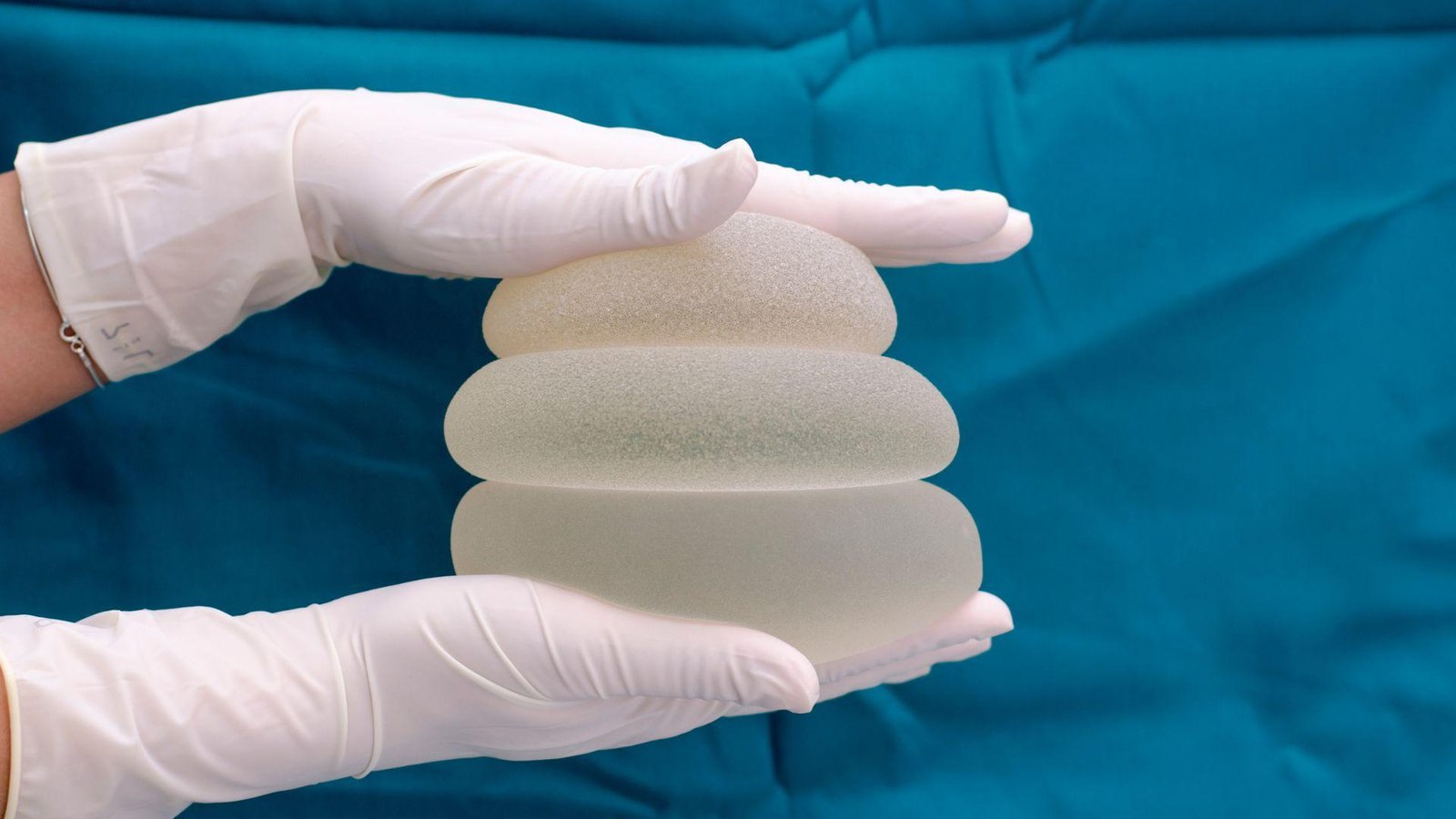

In healthcare, silicone’s biocompatibility, flexibility, and sterilization resistance make it suitable for:

· Medical implants

· Catheters and tubing

· Wearable health devices

· Surgical instruments

· Pharmaceutical packaging

The aging global population and rising healthcare expenditure are further driving demand for medical-grade silicone materials.

In November 2025, Elkem introduced SILBIONE™ LSR Select EC 70, a new generation medical-grade liquid silicone rubber developed for wearable and diagnostic applications. Its high electrical conductivity and certified biocompatibility reflect the industry's push toward precision healthcare innovation.

In electronics, silicone is used for encapsulation, potting, insulation, and thermal management of sensitive components. With rapid miniaturization of devices and the expansion of smart technologies, silicone demand is expected to remain strong.

Challenges in the Global Silicone Market

Volatility in Raw Material Prices

Silicone production relies heavily on silicon metal and other specialized inputs. Fluctuations in raw material prices can significantly affect manufacturing costs and profit margins.

Global supply chain disruptions, energy price volatility, and geopolitical uncertainties create instability in silicon metal pricing. This unpredictability impacts pricing strategies and can influence end-user affordability.

Manufacturers must adopt strategic sourcing and operational efficiency measures to mitigate cost pressures.

Environmental Regulations and Sustainability Concerns

While silicone products have long lifespans and durability advantages, environmental regulations surrounding emissions during manufacturing and end-of-life disposal are becoming stricter.

Governments worldwide are implementing policies aimed at reducing carbon footprints and improving recyclability. Compliance with environmental standards may increase operational costs for silicone producers.

However, these challenges also create opportunities for innovation in greener production technologies and circular material solutions.

Market Insights by Type

Elastomers Silicone Market

Silicone elastomers dominate the market due to their flexibility, resilience, and temperature resistance. They are widely used in seals, gaskets, hoses, insulation components, cookware, wearable technology, and personal care products.

Their biocompatibility also makes them essential for medical devices. Growing demand for electric vehicles and renewable energy systems further boosts the need for high-performance elastomers.

Resins Silicone Market

Silicone resins are extensively used in coatings, adhesives, and electrical insulation. They offer superior thermal stability, weather resistance, and durability compared to many organic resins.

Applications include protective coatings for buildings, machinery, and electronic devices. Their performance in extreme working conditions ensures strong demand across industrial sectors.

Construction Silicone Market

The construction segment remains one of the most significant contributors to silicone consumption. Silicone sealants and adhesives are essential for modern building systems due to their flexibility and resistance to environmental stress.

As green building standards gain momentum, silicone materials play a vital role in improving insulation and reducing maintenance requirements.

Transportation Silicone Market

In transportation sectors such as automotive, aerospace, rail, and marine, silicone enhances performance, durability, and safety. With the growth of electric and hybrid vehicles, silicone materials are increasingly integrated into battery systems and electronic assemblies.

Healthcare Silicone Market

The healthcare segment continues to expand rapidly. Silicone’s non-reactive nature and compatibility with sterilization methods make it indispensable for long-term medical applications.

As healthcare technologies evolve globally, silicone remains central to medical innovation.

Regional Market Highlights

United States

The United States represents a mature yet steadily expanding silicone market. Demand spans construction, automotive, healthcare, electronics, and renewable energy industries.

The growth of electric vehicles, solar energy installations, and advanced electronics continues to stimulate silicone consumption. Strong research and development activities, along with advanced manufacturing capabilities, support sustained innovation.

In January 2026, STUFF Manufacturing began production at its new silicone molding facility in California, emphasizing domestic manufacturing resilience and supply chain efficiency.

United Kingdom

The United Kingdom silicone industry is supported by construction, healthcare, and automotive sectors. Increasing emphasis on sustainable construction and electric vehicle development fuels market growth.

In December 2024, Osteotec re-launched its Silicone Finger Implant in CE-marked regions following updated certification under European Medical Device Regulation standards.

India

India’s silicone market is growing rapidly due to expanding infrastructure, automotive production, and healthcare investment. Urbanization and government support for domestic manufacturing are creating favorable conditions for silicone adoption.

In July 2022, WACKER inaugurated a new silicone production facility in Panagarh, strengthening supply capacity for medical and electromobility applications.

Saudi Arabia

Saudi Arabia’s silicone market benefits from infrastructure development, oil and gas industry expansion, and economic diversification initiatives. Increased investment in healthcare and industrial sectors further supports demand growth.

Market Segmentation

By Type

· Elastomers

· Fluids

· Resins

· Gels

· Others

By End Use

· Industrial Processes

· Construction

· Personal Care & Consumer Goods

· Transportation

· Electronics

· Healthcare

· Energy

· Others

By Region

· North America

· Europe

· Asia Pacific

· Latin America

· Middle East & Africa

Competitive Landscape

Key global players in the silicone market include:

· Shin-Etsu Chemical Co. Ltd

· Wacker Chemie AG

· Illinois Tool Works Inc.

· Evonik Industries AG

· Kemira Oyj

· Dow Inc.

· Elkem ASA

· Kaneka Corporation

Companies are evaluated based on:

· Company Overviews

· Key Personnel

· Recent Developments

· SWOT Analysis

· Revenue Analysis

Intense competition, continuous innovation, and strategic expansions characterize the industry.

Future Outlook

The silicone market’s projected growth from US$ 16.83 Billion in 2025 to US$ 26.88 Billion by 2034 underscores its expanding relevance across industries.

Future growth will likely be shaped by:

· Expansion of renewable energy systems

· Increased electric vehicle production

· Advanced healthcare technologies

· Sustainable construction initiatives

· High-performance electronic miniaturization

Silicone’s adaptability ensures that it will remain a preferred material for emerging technologies and environmental solutions.

Final Thoughts

The global silicone market is on a steady upward path, driven by its unmatched performance characteristics and expanding industrial applications. With a projected CAGR of 5.34% through 2034, the industry reflects both resilience and innovation.

Despite challenges such as raw material volatility and environmental regulations, continued advancements in sustainable manufacturing and high-performance formulations are strengthening market foundations.

In a world demanding durability, flexibility, and sustainability, silicone stands as one of the most indispensable materials shaping modern industry and technology.