Self Pierce Riveting: A Modern Solution for Efficient Metal Joining

In today’s advanced manufacturing landscape, achieving reliable, high-speed metal joining is critical for automotive, aerospace, electronics, and industrial applications. Self pierce riveting (SPR) has emerged as a game-changing technology, enabling manufacturers to join multiple layers of metal without pre-drilled holes or welding. At Heron Welder, we provide cutting-edge SPR systems designed to optimize productivity, precision, and durability for OEMs, automation integrators, and factory decision-makers.

What is Self Pierce Riveting?

Self pierce riveting is a mechanical fastening technique used to join two or more layers of sheet metal. Unlike traditional riveting or spot welding, SPR uses a semi-tubular rivet that pierces the top sheet(s) and flares into the bottom sheet, creating a robust, permanent mechanical joint.

Key Principles of SPR:

-

Rivet Selection – The rivet material and diameter are chosen based on the metal type and thickness. Aluminum, steel, and coated sheets all require specific rivets to ensure joint integrity.

-

Punch and Die Mechanism – SPR machines employ a hydraulic or servo-driven punch that forces the rivet through the sheets into a die, flaring the tail of the rivet to lock the materials together.

-

No Pre-Drilling Required – One of SPR’s major advantages is the elimination of pre-drilled holes, reducing processing time and maintaining surface integrity.

Applications of Self Pierce Riveting

SPR technology is highly versatile and is widely adopted in modern manufacturing. Key applications include:

Automotive Manufacturing

SPR is extensively used in car body assembly to join aluminum and high-strength steel panels, ensuring lightweight structures without compromising safety. Panels for doors, hoods, and roof modules benefit from strong, vibration-resistant joints.

Aerospace and Transportation

In aerospace, SPR enables joining of thin aluminum alloys and hybrid materials, reducing weight while maintaining structural integrity a crucial factor for fuel efficiency.

Electronics and Appliance Production

For electrical enclosures, air conditioning units, and other appliances, SPR provides clean, consistent joints without heat distortion, which is critical for sensitive electronic components.

Multi-Material Joining

With the increasing use of mixed metals like aluminum-to-steel combinations, SPR offers a reliable alternative to welding, which may be unsuitable for dissimilar metals due to thermal expansion and corrosion concerns.

SPR vs. Traditional Welding

Understanding the differences between SPR and conventional welding techniques helps manufacturers choose the right solution for their production line.

| Feature | Self Pierce Riveting | Spot Welding |

|---|---|---|

| Material Compatibility | Steel, aluminum, coated metals | Mostly steel; limited aluminum |

| Heat Effect | Cold process; no heat distortion | Generates localized heat; potential warping |

| Process Speed | High-speed automation possible | Moderate speed; requires electrode maintenance |

| Maintenance | Minimal, mostly mechanical | Electrode replacement, regular calibration |

| Multi-Layer Joining | Up to 5 sheets | Typically 2-3 sheets |

| Corrosion Resistance | Excellent when combined with coatings | May require post-treatment |

SPR offers faster cycle times, higher flexibility, and lower thermal impact, making it ideal for modern automated production lines.

Best Practices for Implementing SPR

To maximize the benefits of self pierce riveting, manufacturers should follow these best practices:

-

Material Assessment – Analyze sheet thickness, coating, and mechanical properties to select the correct rivet type.

-

Machine Calibration – Ensure SPR machines are properly calibrated for force, speed, and die alignment to prevent joint defects.

-

Quality Control – Use optical or ultrasonic inspection systems to verify rivet flaring and joint strength.

-

Integration with Automation – SPR systems can be integrated with robotic arms, conveyors, and sensors for fully automated assembly lines.

-

Regular Maintenance – Keep dies, punches, and rivets in optimal condition to maintain consistent quality.

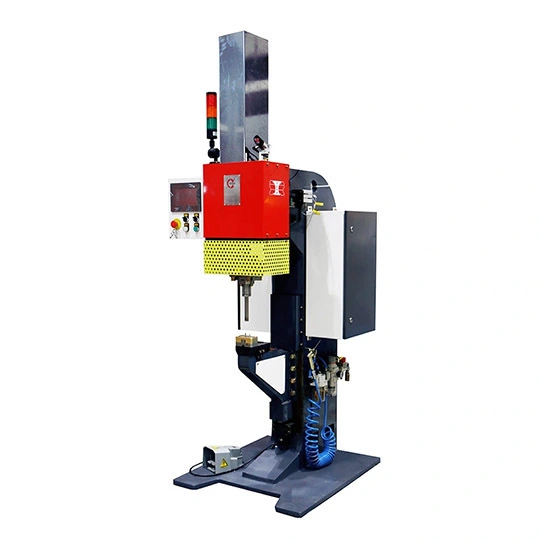

Why Choose Heron for Self Pierce Riveting Solutions

At Heron Welder, we combine technical expertise, industrial-grade machinery, and automation support to deliver SPR solutions tailored to your production needs. Our SPR systems are designed for:

-

Precision and Reliability – Ensuring every rivet meets strict quality standards.

-

Scalability – From small-batch production to high-volume automotive assembly.

-

Integration Capability – Compatible with robotic automation for seamless workflow.

-

Expert Support – Guidance from design and application engineers to optimize processes.

Heron’s global experience in resistance welding, clinching, and automated joining solutions positions us as a trusted partner for manufacturers seeking efficient, high-quality metal joining technologies.

FAQs About Self Pierce Riveting

1. Can SPR join dissimilar metals?

Yes. SPR is ideal for joining aluminum to steel or coated metals, avoiding the corrosion and thermal issues associated with welding.

2. How many sheets can SPR join simultaneously?

Typically, SPR can join up to 5 layers, depending on material thickness and rivet size.

3. Does SPR require post-processing?

No heat-affected zones are created, so post-processing is minimal, though surface finishing may be applied for aesthetics or corrosion protection.

4. Is SPR suitable for robotic automation?

Absolutely. SPR is fully compatible with industrial robots, enabling high-speed, repeatable operations.

5. What industries benefit most from SPR?

Automotive, aerospace, electronics, appliances, and multi-material assembly sectors gain the most from SPR’s efficiency and strength.

Conclusion: Elevate Your Metal Joining with Heron

Self pierce riveting is revolutionizing modern manufacturing by offering strong, reliable, and efficient metal joining. For factories aiming to improve productivity, reduce thermal distortion, and handle multi-material assemblies, SPR is a proven solution.

Heron Welder provides customized SPR systems, integration support, and technical expertise to help you implement high-performance, automated joining solutions.

Contact Heron today to request a quote or consult with our engineers and discover how our self pierce riveting solutions can optimize your production line.